Circulation Pump Definition

This high temperature pumps are custom designed to fulfill the requirements of higher technology. Considering the unique feature of each application in design, we treat this as high level of safety for thermal stress, thermal simulation and sealing.

Hot Water Circulation Pump: Medium TEMP: 80-280. C Liquid: Clean Water

Centrifugal Pump:

- Civil Level for Heater, Utilities Building etc.

- Industrial pump for HRSG, Chemical Device, Power Plant

- Critical application for high Pressure & TEMP, supercritical Power Plant; Solar Power (CSP)

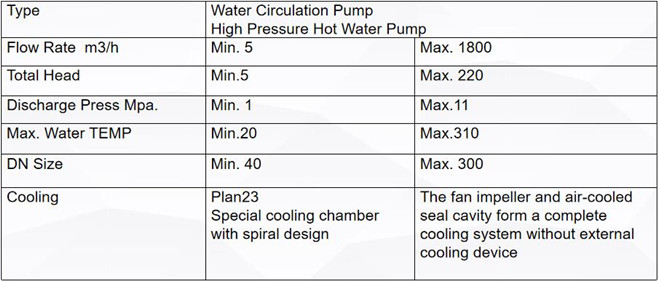

Parameters & Classification

Key Feature design as follow:

★ Materials of construction, consideration of the stress & liquid corrosion, which can be chosen by stainless steel, or hastelloy alloys if necessary

★ Design according to the high TEMP to have different cooling ways and sealing

★ Thrust & Radial Bearings to be balance in high quality

★ Based on International Standard & Code design, like ASME or API, IEEE for Electrical

Arrangement:

Arrangement

- Single Stage & Single Suction

- Two Stage & Single Suction

- Single Stage & Vertical Installation

Parameter Set/Data Sheet

| Parameters | Middle Size | TEMP:≤250’C Suction Pressure:5Mpa |

| High Pressure | TEMP:≥250’C Suction Pressure:10-30Mpa |

Application & Marketing

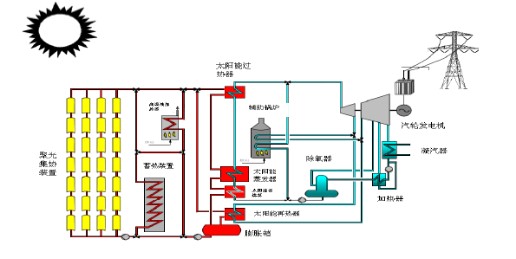

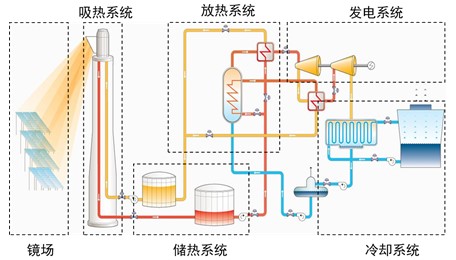

Applications — Concentrated Solar Power

Hot water circulation pump for CSP Steam System

Solar Power is the renewable Power in now days and would play more and more important roles in the Energy Power Industry.

We could offer the product with higher pressure (up to 30Mpa) and hot water condition (TMEP up to 330’C) with no Seal less risk, this is based on the Technology that applied to Super Critical Power Plants across the whole world with more than 50-60years technology

Vertical or Horizontal layout , suspended in piping system

Pump case and stator case are designed to be one pressure vessel with no pressure difference, to have one shaft and make sure there is no leakage, no mechanical seal.

Free of conventional mechanical sealing, to ensure completely free of leakage. Widely used in extremely high temperature and high-pressure situation, proper prove to the most critical requirement to operation security.

Applications

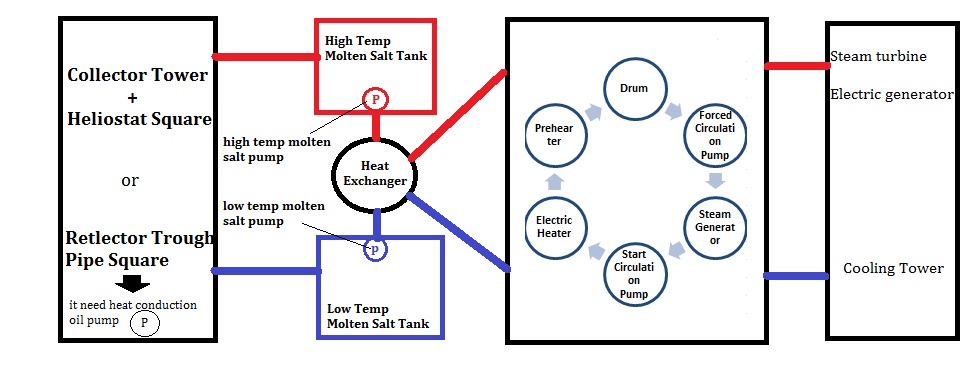

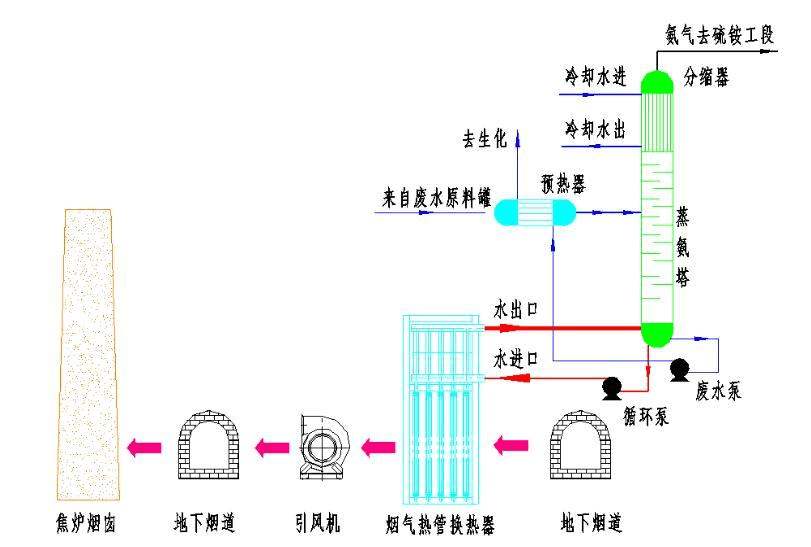

Hot water circulation pump for HRSG —Heat Recovery Steam Generator

- Iron and steel metallurgy industry

- Biomass waste power generation

- Gas Power

- Coking furnace

- Glass Furnace

Petrochemical catalytic Unit— TEMP adjustment for Reaction

- Chemical: Sulfuric acid production unit, medium and heavy oil gasified for synthetic ammonia production (TEMP@Suction 1350’C,Pressure 3.2-4.0Mpa U type Boiler)

- Petrochemical: Petroleum cracking unit , Catalytic cracking, Pyrolysis of petroleum hydrocarbons to ethylene requires high heat transfer rate boilers, such as elliptical collector tube sheet waste heat boiler

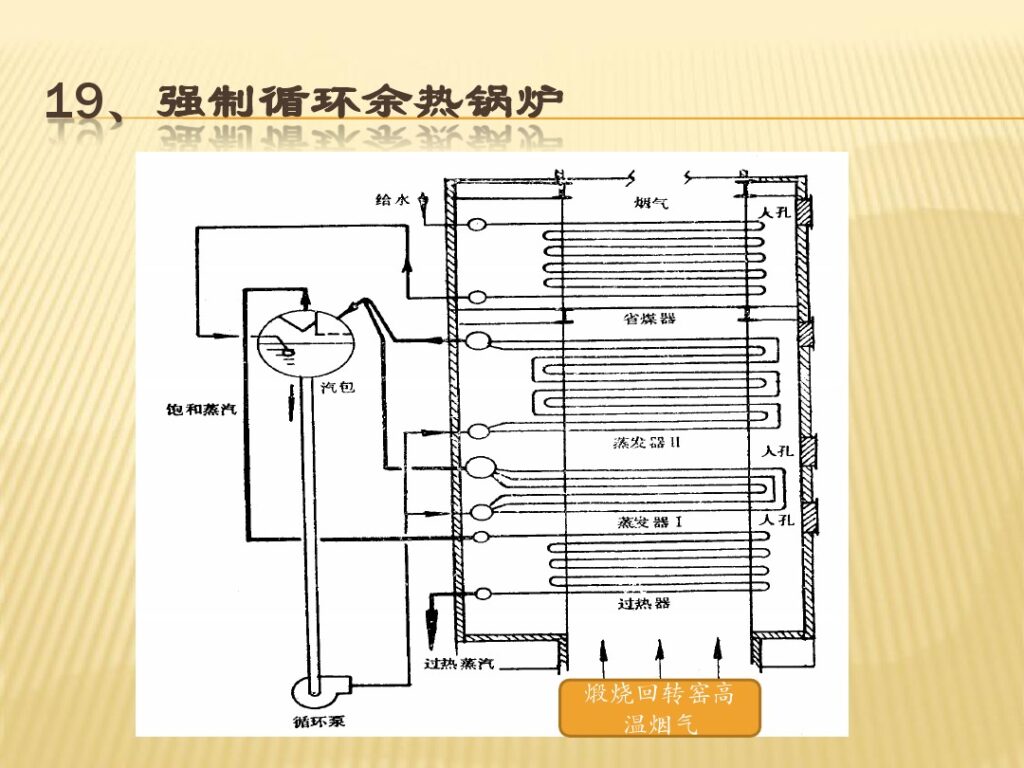

Forced Heat Recovery Boiler

Forced Heat Recovery circulation boiler, they have to use circulation pump to build up this steam circle

——- HRSG

Applications

- metallurgy

- Steel

- Gas Power

- Coking

Chemical Reaction Recovery

Catalytic cracking waste heat boiler is used in the catalytic cracking and pyrolysis unit of heavy oil in petrochemical system refinery.

During operation, the high-temperature flue gas energy of the catalytic device is recovered for the saturated steam generated by the oil slurry steam generator and external heat collector in the super heater and the medium pressure saturated steam produced by ourselves to form the medium temperature and medium pressure superheated steam device

For the exothermic reaction of synthetic ammonia, the temperature shall be properly absorbed to prevent the temperature in the tower from being too high.

Pump Technical Information

Outline Arrangement

Horizontal Unit Set with Basement (Including Heat Exchanger & Inspection device etc. )

Vertical as mounted on pipeline with Basement or not

Data Sheet

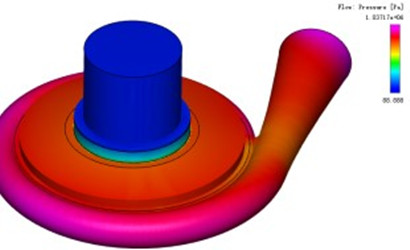

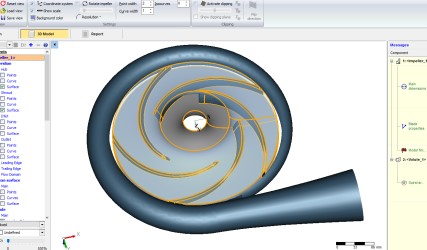

Hydraulic Design

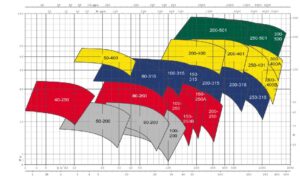

Performance Curve

Simulation

Mechanical Advantages

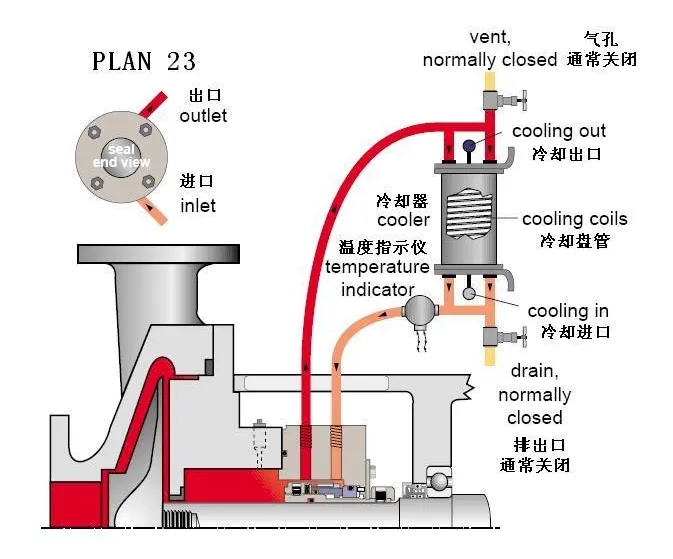

Double ways for Cooling to ensure more reliable product

Labyrinth cooling for Mechanical seal

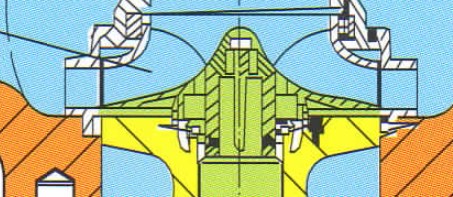

Bearing assembly for front & cover-end to ensure balance while in operation

Inspection for TEMP Monitor and Vibration

Please leave your message or email with pump data requirements, for which we could have a selection to have a technical proposal to you!