General Information

Flowflyer Electric Actuator succeeds in integrating latest automation technologies in field communication, local displaying, controlling technology, and advanced manufacturing techniques, with customer needs.

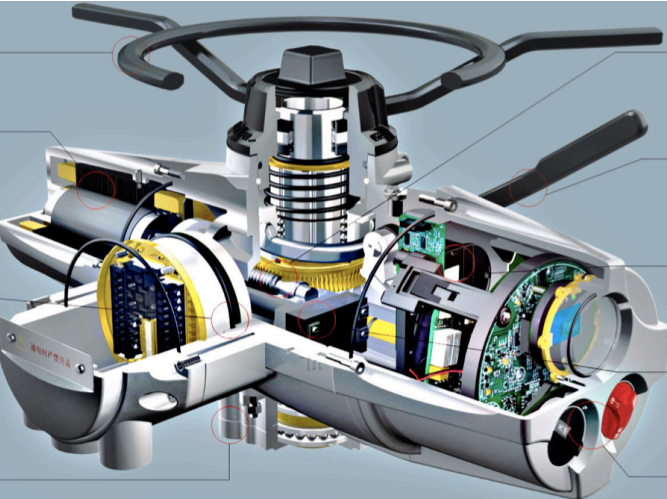

Work Principle

Using a single-phase or three-phase motor to drive gears or worm gears, and finally driving the valve stem nut, the valve stem nut causes the valve stem to move and open or close the valve. Multi turn electric actuators can quickly drive large-sized valves. In order to protect the valve from damage, the limit switch installed at the end of the valve stroke will cut off the motor power supply. At the same time, when the safety torque is exceeded, the torque sensing device will also cut off the motor power supply. The position switch is used to indicate the on/off status of the valve. The handwheel mechanism installed with the clutch device can manually operate the valve in case of power failure.

Movement Types

Actuator can be classified into:

Multi-turn

Part-turn

Usage Condition

Actuator can be classified into:

Outdoor type

Explosion-proof type

Control Valve types

Actuator can be classified into:

Part-turn

Linear and rotary

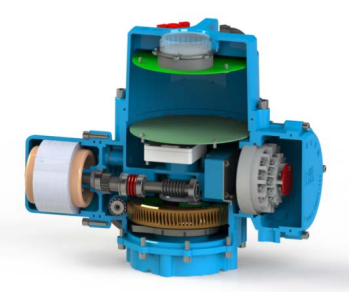

Product Structure

Actuator can be classified into:

Basic type ( mechanical type)

Integration type (mechanical and electrical type)

Intellectual type

A) Driving motor

Motor is low-inertia and high-torque, so that actuator can reach suitable torque promptly. There is over-temperature protection to protect motor from too high temperature.

B) Sealing structure

A double sealing design structure to ensure actuator is completely resistant to water and dust. The standard product protection grade is IP67 with the maximum reaching IP68

C) Human-machine interface LCD

Graphic dot matrix LCD with background lighting displays torque, valve position, limit setting and other working status and alarms

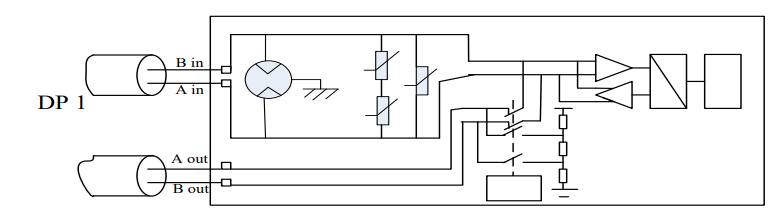

D) Field Bus

Communication module has independent structure connected to motherboard. Actuator currenty Modbus, Profibus, HART, FF and DeviceNet etc.

E) Housing anti-corrosion

Exterior surface is painted by special metal of aluminum alloy with tough painting film and strong adhesion. With strong resistance to ultraviolet and corrosion and high fullness. Water-proof complies with IP68, 7m/72h, -30’C~+70’C. Anti-explosion shell follows Exd II CT4

F) Terminal Box

Independent sealed terminal box ensures enclosure integrity together with field wiring, is also explosion-proof.

G) Infrared remote control

The actuator is equipped with infrared remote-control technology, so that operator can communicate with actuator in distance. In hazard applications, remote control function would protect operator from danger

H) Output connection

The actuator flange and output meet the ISO5210/5211 standard. We can also provide customized connections.

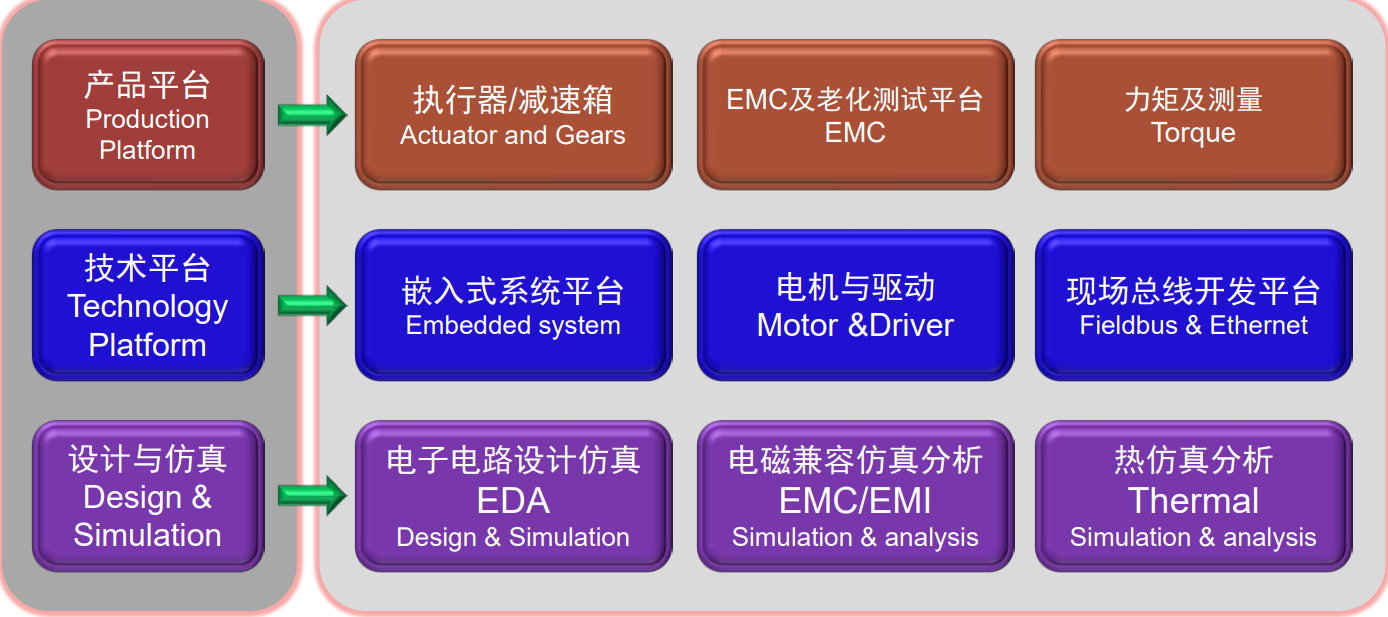

Technical Advantage:

- Multi-functionaltechnology platform

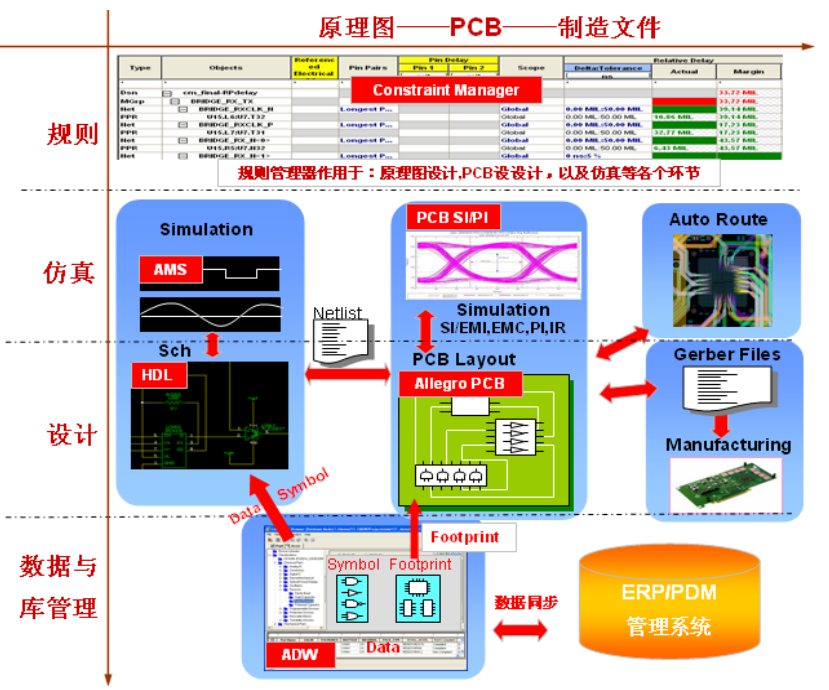

2) Electrical Design Automation Platform

Schematic Design—-Mixed Signal Simulation—PCB design—Signal Integrity Simulation—-Power Integrity Simulation—Machinery & Inspection—-Design Documents Collection—Central Library Management System

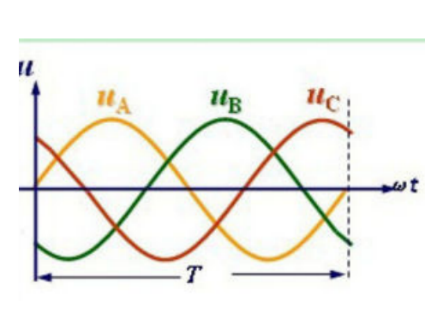

3) Advanced phase detection technology

A: Automatic phase sequence adjustment

B: Lack of phase protection

4) Valve position detection

A: Using the most advanced magneto electric absolute encoder

B: Support remote transmission suitable for actuator split design

C: The maximum output turns can reach 12000 turns

5)Intelligent control

- PROFIBUS/FF/HART/MODBUS/BACNET

- Support DPV0/DPV1 function;

- Support redundancy

PROFIBUS baud rate 9.6K~12M adaptive;

- Support EDDL technology;

- Support FDT/DTM technology;

Three level protection technology ensures the safety and reliability of control functions

- Independent fieldbus protocol stack technology, certified internationally

Please leave your message or email with pump data requirements, for which we could have a selection to have a technical proposal to you!