Double Layer wedge washer

Double layer wedge type shock absorber washer

This washer was up-grade & further R&D, manufactured locally in China and launch to marketing. Meanwhile, we still have better designed & Manufactured washer to replace Nord for competitive cost,and we already got National Technical Patent with our local trademark as DQdoub-lock® 。

√ Standard:Both German/France Standard/Code widely used for Siemens、 Bombardier 、MAN etc. train、motor, gear box, or generator。

DIN25201、

NFE25511、

NFE3L etc. serial

√ Certification passed: SGS、TUV、 CSR Lianchen Lab、CARS Test Various assessment report from VIP customers. Because of these recommendations, we have lots of application in railway, Medical, Shipyard, Bridge, tooling machine and even in paper industry

Wedge type washer principle introduction

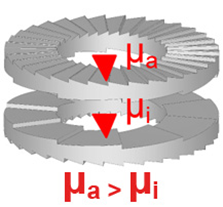

The inner surface of the washer is wedge-shaped. The outer surface is radially serrated.

The friction coefficient µ i on the inner surface of the gasket wedge is significantly lower than that on the serrated outer surface µ a.

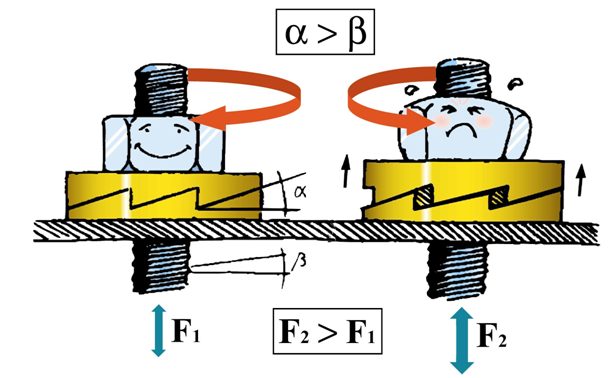

Wedge slope on the inner surface of the gasket( α) Thread angle greater than the corresponding bolt model( β)

Wedge type washer principle introduction

When vibration occurs, the gasket first undergoes loosening and displacement on the smooth inner surface with low friction, and there is no relative displacement on the outer surface, resulting in a rising angle α greater than β, Thread the bolt and stretch it. The clamping force F2 is greater than the clamping force F1 when tightened.

The increased clamping force will cause the gasket to undergo reverse displacement and reset on a smooth inner surface.

Wedge type washer principle introduction

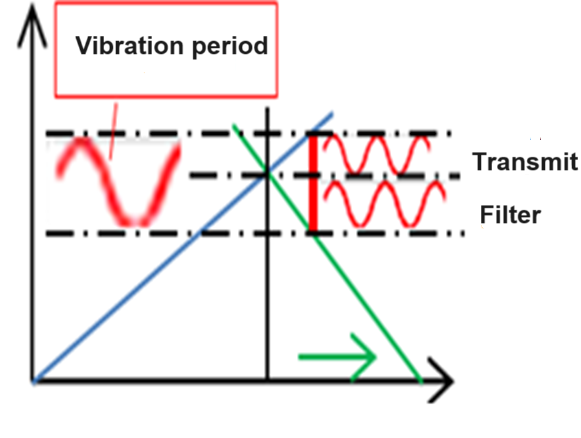

When vibrating, the gasket converts and consumes vibration in this reciprocating motion. Wedge type washers are elastic connections that do not increase the stiffness of the connection. They can convert a large amplitude vibration into multiple small amplitude vibrations and filter out a portion, reducing the vibration experienced by the bolts and reducing the amplitude of the connected structural components.

This axial force anti loosening design originated from Germany is a revolutionary anti loosening principle, overturning the mechanical anti loosening and friction anti loosening mentioned in the Mechanical Design Manual.

Mechanical anti loosening (such as ear pieces, split pins, welding, etc.): bolts are prone to breakage, thread threads may be ground flat, and nuts cannot prevent loosening. Friction prevents loosening, which is a process of overcoming friction and will eventually loosen.

Wedge type washer principle introduction

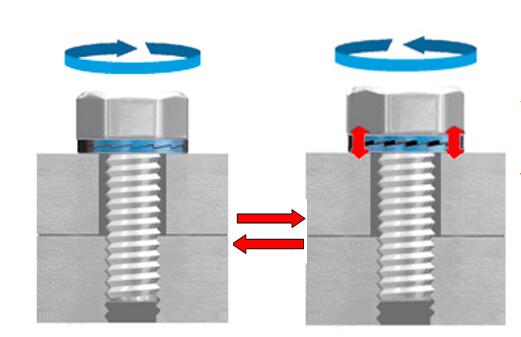

When the equipment vibrates, displacement occurs on the inner surface of the gasket. The surface of the washer does not experience relative displacement with respect to the nut and workpiece

The surface of the workpiece is tightly sealed with the gasket, which will not rust the workpiece surface

Other connection methods may cause vibration displacement on the workpiece surface, which can actually scratch the workpiece surface and lead to rusting

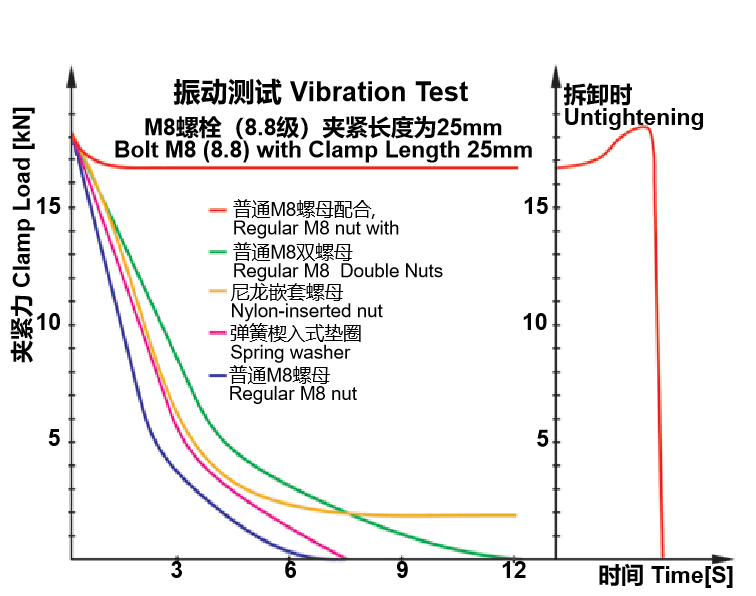

The Junker Vibration Test

Junker Vibration Test is applied for DIN65151-2002 Standard

The dynamic test (vibration test) of locking characteristics of fasteners under lateral load conditions is a professional method used to test and compare the safety of bolted connections

You can check the same video on line for testing such vibration effect by using different washer or gaskets.

The Junker Vibration Test Comparison Chart

Traditional anti loosening methods include:

1 Use high-strength bolts and nuts to increase torque and bring the bolt close to the yield point of plastic deformation. Make the initial preload higher, as reflected in the curve starting at the top of the X-axis

2. Increase the friction coefficient (serrated washer, nylon nut) or friction contact surface (flange nut, double nut) to increase friction and make the curve smoother.

When disassembling the nut, the bolt is stretched and the clamping force significantly increases. This is precisely the characteristic of wedge washers: vibration does not loosen but instead increases clamping force.

As long as it is prevented from loosening through friction, loosening is the process of overcoming friction, and the friction will gradually decrease, and the final loosening is inevitable.

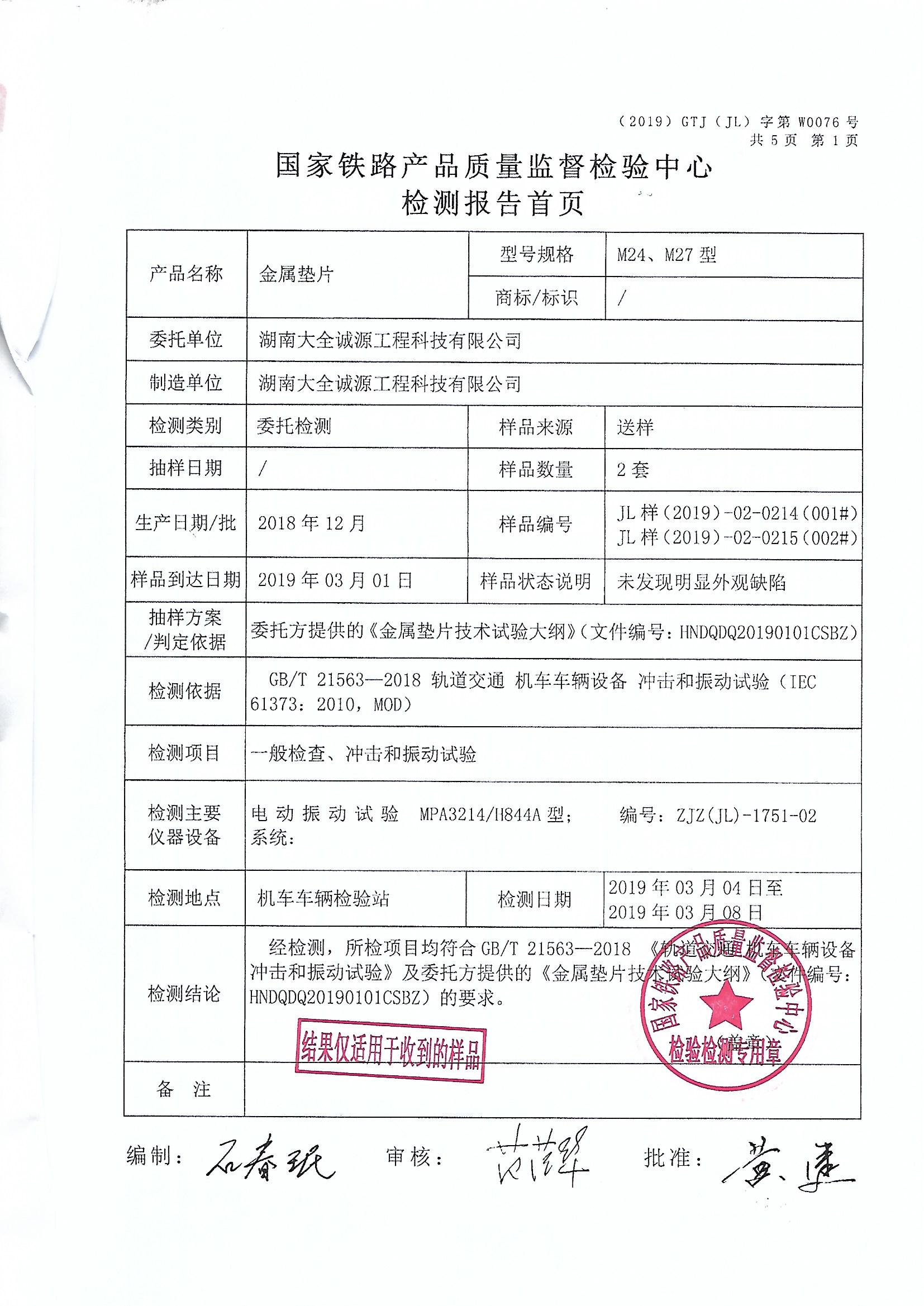

Test Certification from Third Party

SGS

TUV

Railway Science Institute Report

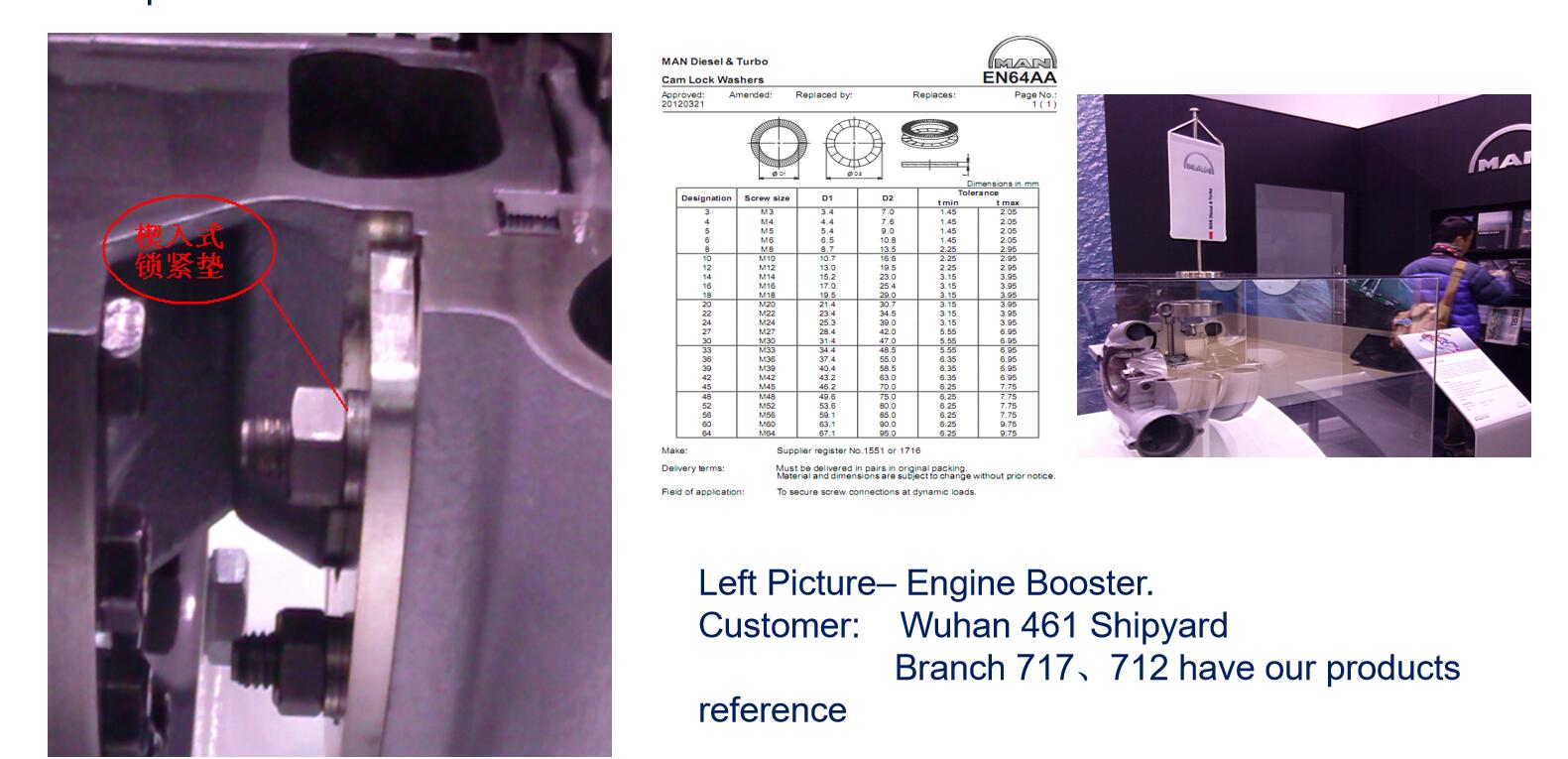

Applications — Dieseal Engine Booster

World famous Commercial Car-manufacture MAN’s diesel engine’s mechanical drawing has marked lots of such washer to secure safety operation。

Applications — Offshore Platform

—Deep sea drilling vessel “Tiger”by Sichuan Honghua

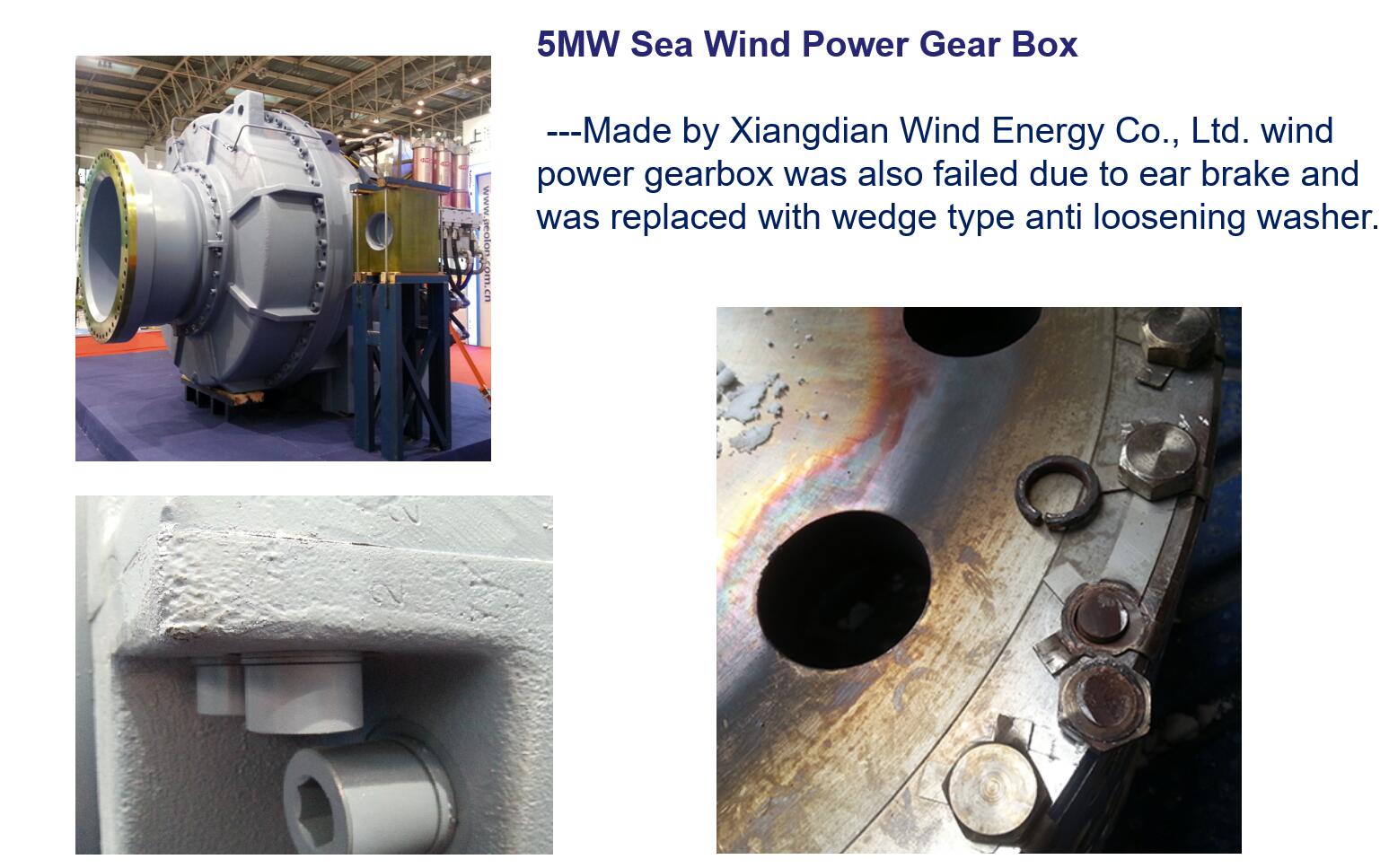

Applications—- Wind Power Gear Box

Applications—– Power Generation

Study Case Delingha 50MW Solar Thermal Power Station

Applications —-Engineering machinery – Gearboxes connected to turbine rods

Applications—–Bridge expansion joints

Study Case: Hunan Expressway Management Bureau

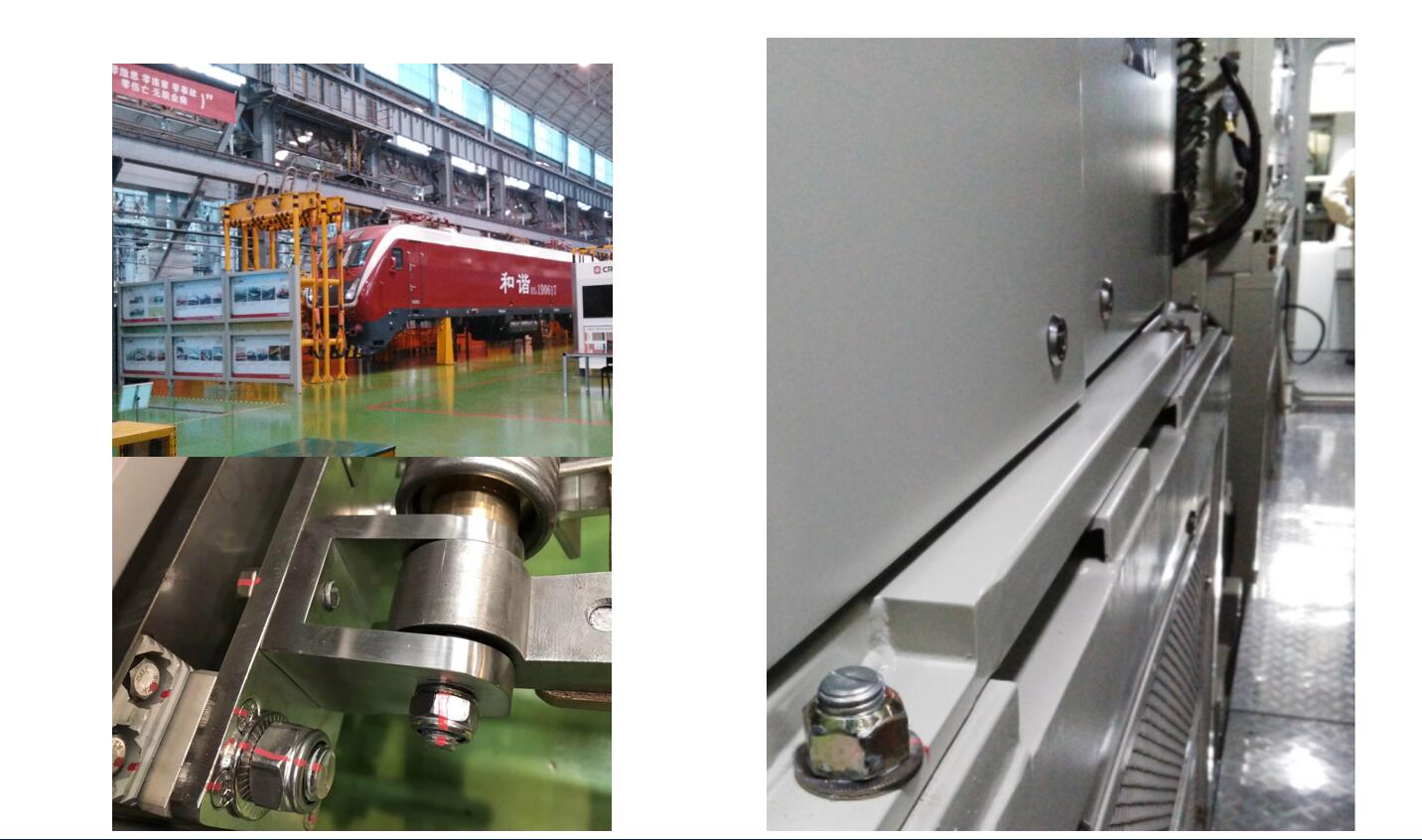

Applications—- Rail engineering vehicle by CSR Vehicles

Study Case: Export to South Africa and Singapore, It was required to install Self-locked Stainless Steel Wedge Washer

Applications —-High Speed Train by CSR

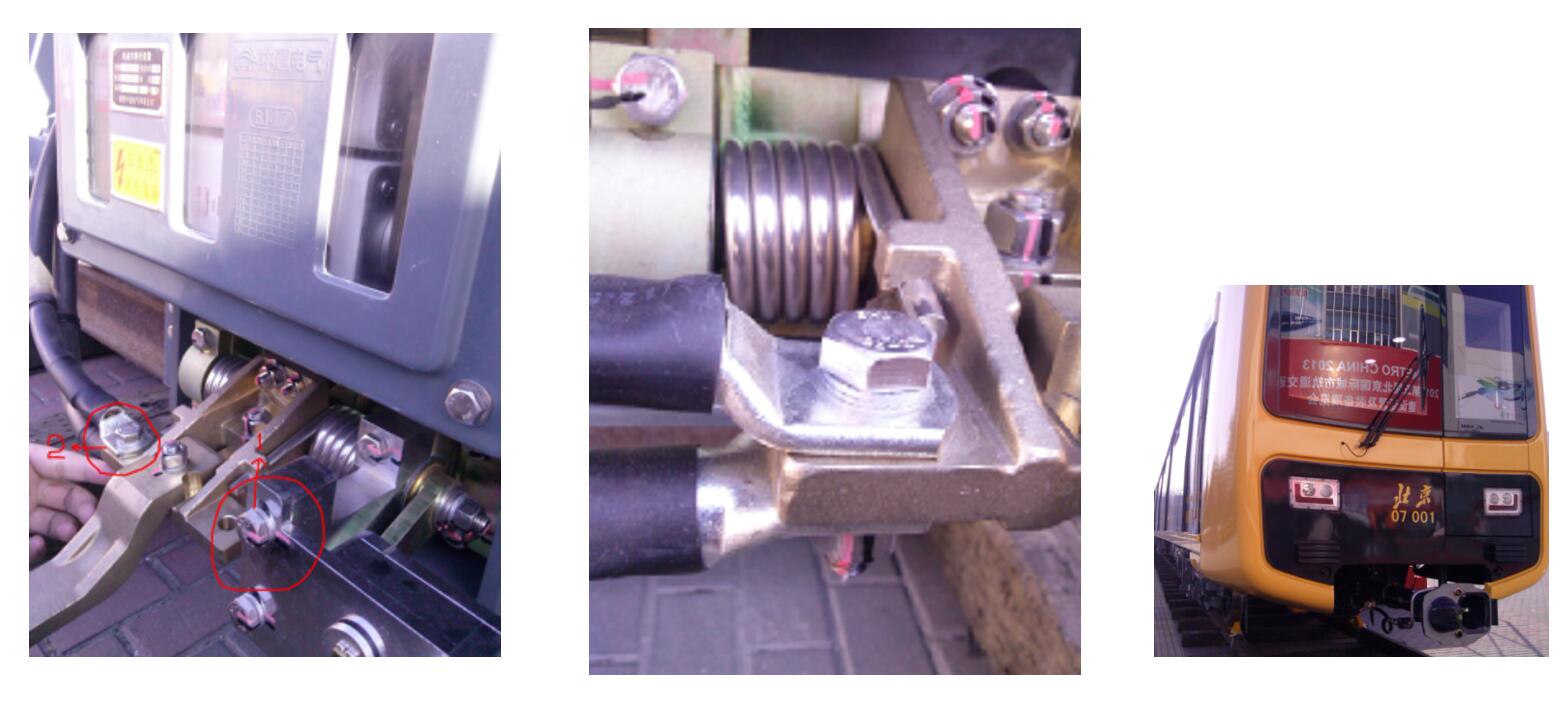

Study Case: Electrical Control Box & Underbody bogie

Applications—-Subway of Beijing Line 7,10

Technically from Siemens subway.

The bottom current collector of the urban rail is manufactured by Xiangtan Zhongtong Electric.

Case Analysis—- Spot welding+shape locking connection

This type of rigid connection method will wear out and become smooth after 2 months of use, causing the entire connection part to withdraw, resulting in a gap between the spacer and the steel rail. At this time, it is necessary to cut open the welded parts, replace the bolts and washers, otherwise there will be a gap between the spacer and the steel rail, which will change the gauge and affect driving safety.

After using the wedged washer for two months, the personnel responsible for tightening and filling the gaps did not notice any looseness during each patrol, and the bolt threads were intact because this elastic connection has the function of shock absorption.

Please leave your message or email with pump data requirements, for which we could have a selection to have a technical proposal to you!