Low Voltage Customized Motor

Low Voltage Customized Motor( with your own Logo)

We have huge manufacture in China with professional process of motor producing by rich local material souring.

This Low voltage IEC and NEMA motor is designed with the new European standard for high efficiency, international standard 60034-30-1 for efficiency IE2, IE3, IE4 & NEMA from North American.

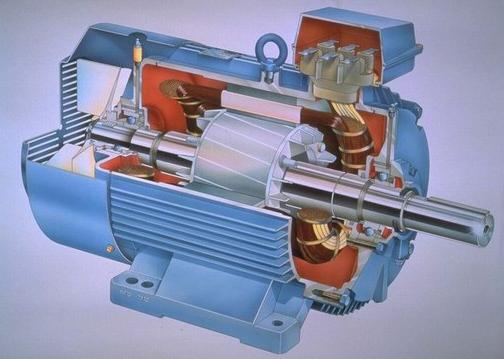

The motor is totally enclosed, fan cooled, with squirrel cage rotor

There are Aluminum frame and cast iron frame

Single Speed three phase cage induction motors with 50HZ or 60HZ; rated voltage up to 1000V

S1 Duty, with 2,4,6,8 pole as options

IE2 high efficiency from 0.12-375KW

IE3 high efficiency from 0.12-375KW

IE4 super premium efficiency from 0.12-375KW

All Types of Motor could be offered:

1, IEC Motor: Generally, it could be operated in most of the industry

2, NEMA Motor: Centrifugals Blowers, Roof Vents, Sidewall Ventilators

3, S.S Motor: Stainless Steel Motor for Food and Chemical

4,H.T Motor: High Temperature Condition/ Avoiding Smoke

5, VHS Motor: Vertical Hollow Shaft induction motor for deep well pumps

6, Fire Pump motor

7, GOST Motor

8, EC Motor: Electronically Commutated Motors ( Permanent magnet synchronous); efficiency would overcome IE5

Various Certificate has been approved, such as CE, UL, etc.

IEC Motor

Standard & Code:

Ratings and performances: IEC 60034-1 CEI EN 60034-1

Methods for determining losses and efficiency: IEC 60034-2-1

Classification of degrees of protection: IEC 60034-5

Methods of cooling: IEC 60034-6

Terminal markings and direction of rotation: IEC 60034-8

Noise Level: IEC 60034-9

Built in thermal protection: IEC 60034-11

Starting performance of rotating electrical machines: IEC 60034-12

Mechanical Vibration: IEC 60034-14

Dimensions and outputs for electrical machines: IEC 60072-2

| Mounting and Positions | Protection: |

| B3/B35/B5/B6/B7/B8/B14 | IP55 (standard) |

| V1/V3/V5/V6/V18/V19 | IP56 (upon request) |

Applications:

Pumps & Fans

Compressors

Chemical plants

Heavy Duty applications

Key Features:

1, Cooling —IC411 as standard, IC416, IC418, 410 upon request

2, Bearings and oil seals— Ball bearings. Motor with bearing axial constrains have an arrangement with a spring in order to absorb vibrations. Life time is in excess of 40,000hours, for motors with direct coupling

3,Terminal Box & Connection—– Normally equipped with 6 terminal and is made with non hygroscopic and middle resistance material

4,Insulation & Winding —F or H Insulation Class. Cables is coated using a spray with heatproof, humidity-proof, chemical agent and sea-ambient corrosive actions resistant characteristics

5, Technical Data— Locked rotor current(+20% as guarantee); torque(-15%,+25% as guarantee)

6, Frequency variations—Up as 10% of voltage, 5% of frequency and Max. TEMP of 10% raised

7, Voltage— From 220V to 690V, 50HZ or 60HZ

8, Vibration & Overload & Noise information—- Read Brochure as attached

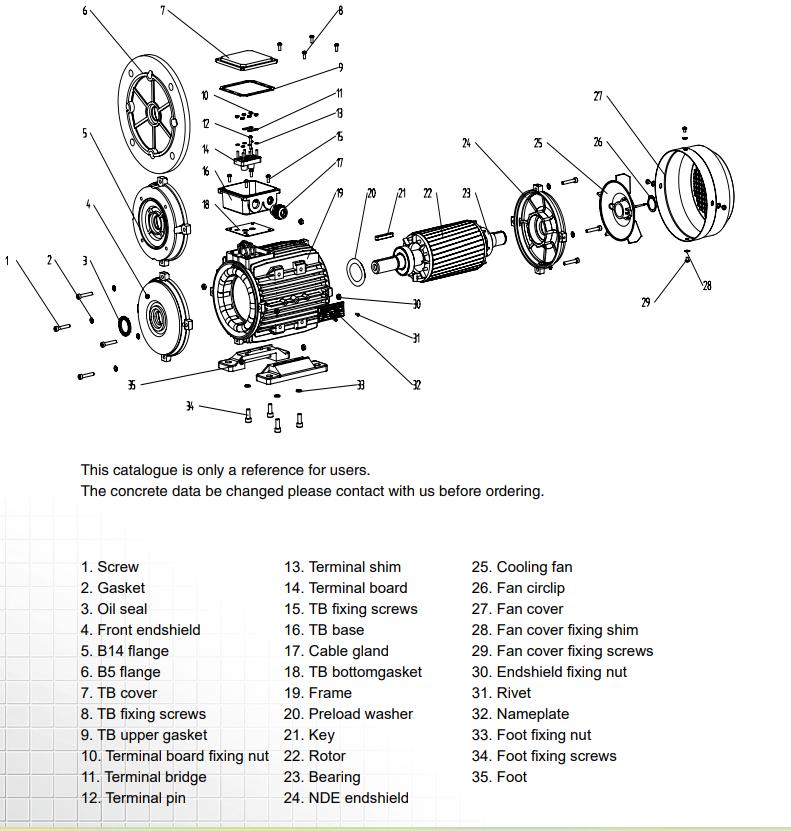

IEC Motor Structure & Spares

The whole motor unit would be produced based on customer’s Requirements, and spares would also be provided for after-sale Service if necessary, to support for business

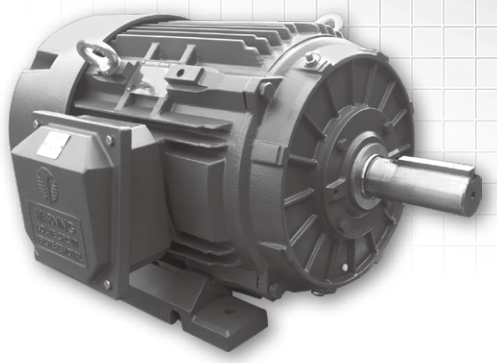

NEMA Motor

Standard Specifications:

Open Drip Proof

3.3” Resilient Cradle/ Thru Bolt Mount ( Ridgid Base available)

Dual Voltage 115/208-230V single phase

Dual Voltage 230/460 Three Phase

Class F Insulation with B Temp rise— 40’C Ambient

Single Phase Automatic Reset Thermal Protection –UL2111

Three Phase Automatic Reset Thermal Protection –UL1004

Inverter Duty Available/ S1

Key Features:

1, Material can be stainless steel or cast iron, which depends on working conditions

2, NEMA service factor 1.15 or 1.25 & NEMA design B & D for 3phase and L for Single

3, Ball Bearings

4, Steel or Aluminum Motor Housing

5, IP55 or IP56 Protection

Applications: ( 3-phase )

Pump

Compressors

Fans

Conveyors

Machine Tools

Petro-chemical plants

Gear Reducers (NEMA Design C)

IEEE-841 Three-phase motor petrochemical motor-NEMA Premium efficiency

This IEEE-841 NEMA Premium efficiency motors are specially suited for pulp and paper mills, steel mills and requiring long life duty

Key Features:

Labyrinth type oil seal on drive end and opposite drive end

External Paint:

Epoxy polyamide enamel, 240h salt spray as per ASTM B117-03

Fan: Conductive plastic or Broze

Please leave your message or email with pump data requirements, for which we could have a selection to have a technical proposal to you!