Canned Motor Pump

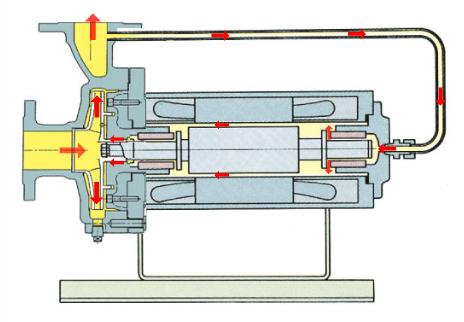

The canned pump is a centrifugal pump, close coupled to a canned Motor in such a way that there is no dynamic shaft seal, no couplings and no ball bearings. The motor is cooled by the pumped liquid and sleeve type bearings are lubricated by the same liquid. This eliminates the need for external lubrication.

The Stator of the driving motor, which is usually three phase squirrel cage induction motor, which is hermetically contained in a stator containment that consist of an external frame tube, out board & inboard end plates and the cylinder liner.

The Rotor which is welded on the shaft, is also encapsulated with a non magnetic liner. Both stator can and the rotor can are seal welded at both ends, and does not allow any part of the motor to be exposed to external environment or internal pumped liquid.

Basic Standard Canned Motor Pump

Parameters:

Capacity:Max. 1000m³/h

Head:Max. 200m

Output:Max.500kW

Applications:

organic & inorganic chemical, vacuum series, high pressure series, other nuclear used radioactive liquid and so on

Key Features:

1, A shaft construction with an external recirculation line for cooling

2, Deliver middle and low temperature liquid that contain solid particles without complete non-leakage

Key Benefits:

No leakage

No external lubrication

Compact design

No shaft seal

Low noise and vibration

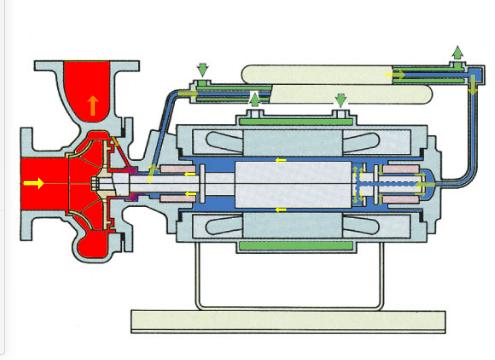

High Temperature Liquid Pump

Parameters:

Capacity:Max. 1000m³/h

Head:Max.200m

Output:Max.

Temperature:Max. 450’C

Applications:

Hot Oil & Water etc. with High Temperature Liquid

Key Features:

1, This model uses a thermal barrier between the pump case and motor to thermally isolate the motor

2, This pump has an external heat exchanger to keep the motor temperature regulated.

Key Benefits:

No leakage

No external lubrication

Airtight

Compact design

No shaft seal

Low noise and vibration

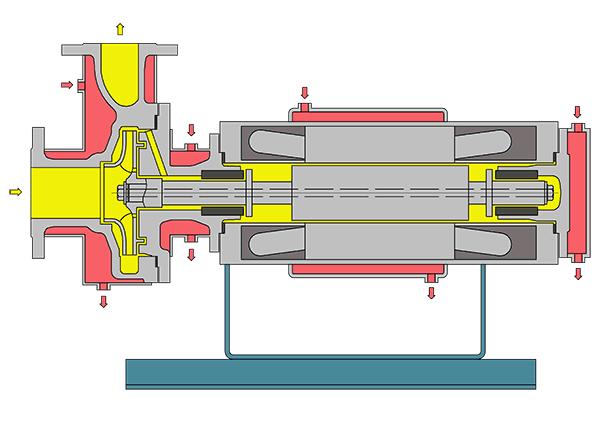

High Melting Canned Motor Pump

Parameters:

Capacity:Max. 300m³/h

Head:Max.90m

Power: Max. 135KW

Applications:

Transport easily crystallized high melting point liquid

Key Features:

1, Uses a series of heating jackets to maintain an increased temperature around the motor. Ideal for handling liquids with high melting points.

Key Benefits:

No leakage

No external lubrication

Jackets for TEMP holding

No shaft seal

Low noise and vibration

No shaft seal

Low noise and vibration

High Melting Canned Motor Pump

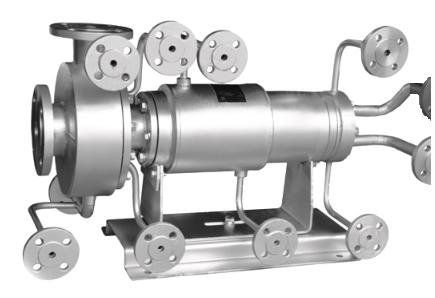

Codes and Compliances: ( For all canned motor pump)

Flange standards available to meet ANSI B73, ISO 2858, GB and other international standards

API 685 design available

Explosion proof design to ATEX II 2G Ex “d” IIC T4 Gb

Materials available to ASTM, EN, GB or other international standards

Please leave your message or email with pump data requirements, for which we could have a selection to have a technical proposal to you!